5-axis milling machine latest addition at etg

The demands on machined parts are constantly increasing. Quantities are increasing, tolerances are becoming smaller and the price pressure is getting higher.

To meet these constraints, etg has purchased a 5-axis milling machine. What sounds so simple is then in the conversion nevertheless often not completely simple. For example, a new foundation with a special load-bearing capacity had to be cast for the machine, which has a dead weight of 8 tons. Fortunately, the gates and conditions on site were such that the machine could then be brought into position with millimeter work.

O-rings as damping elements

O-rings are ring-shaped sealing elements. The name is derived from the round (O-shaped) cross-section of the ring.

Due to their relatively simple shape, O-rings are easy to manufacture industrially.

The sealing type of the O-ring has large, diverse application potential, among other things in automotive or mechanical engineering, but they can also be found in every area of industry.

At etg we have now found a new field of application for O-rings. An O-ring with the appropriate machining can be used as a damping element for a wide variety of vibration compensations.

Removing segments of the O-ring changes the frequency dependence of the damping.

The machinery and know-how of etg allows this machining.

Contact us for further information.

No leak is too small for us - we find it

Leak tests and leak detection with the inert gas helium are now used in many production lines. The design of such test methods is very much dependent on the application and requires a great deal of knowledge, especially when it comes to sealing the test specimens and test chambers.

At etg, such a device is now also used in the clean room. We can use it to perform analyses of high-vacuum seals or permeation tests under clean conditions.

The cleanliness criteria according to DIN 14644 are thus fulfilled.

New clean room

To further improve our high standards, we have invested in a new ISO 7 cleanroom with ESD workstations. In the course of this, our wet chemical cleaning as well as the material lock incl. UV particle inspection were also modernized.

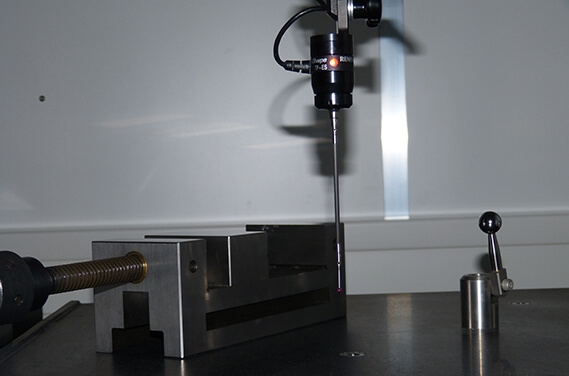

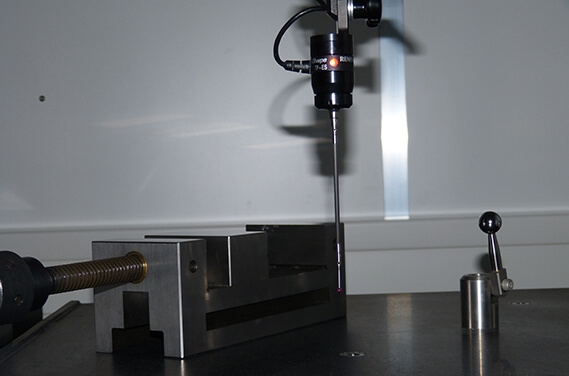

Coordinate measuring machine in the cleanroom

As of now, a coordinate measuring machine is also available in the cleanroom. This means that we are now also able to measure cleaned parts and test assembly processes with regard to their position reproducibility and particle emission in the cleanroom.

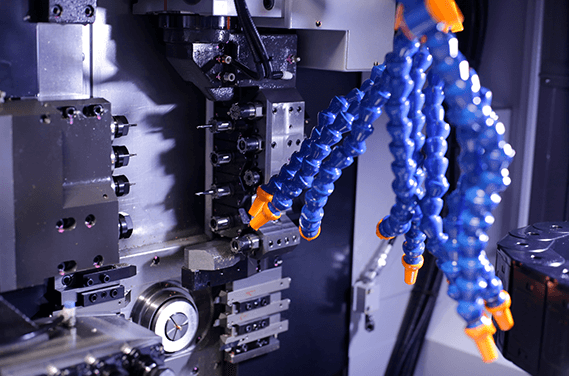

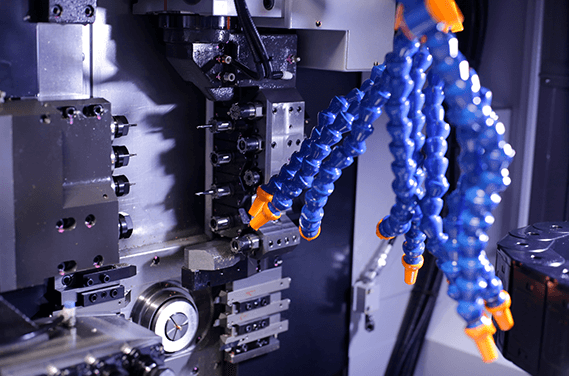

New sliding headstock lathe for highly complex components

ETG in Weiterstadt continues to expand its manufacturing capabilities. In order to continue to be the fastest contract developer and manufacturer in medical technology, we have invested in a new processing machine.

Time is racing

We move in a world where speed is ever increasing. Product development cycles are becoming shorter and shorter - time is racing. Numerous case studies confirm that we can overcome the hurdle of "time" with our optimized processes, motivated employees and by acting effectively. We are happy to support you in reducing your "time to market"!